How does REVITALIZANT work works in XADO Greases?

Demonstration Experiment

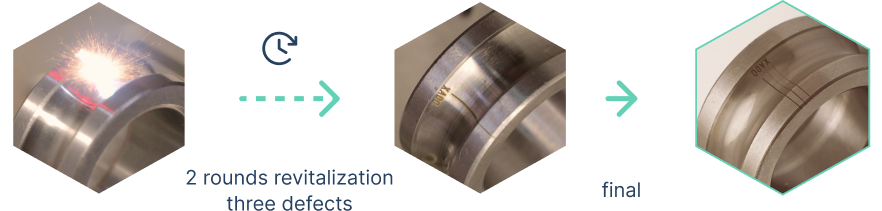

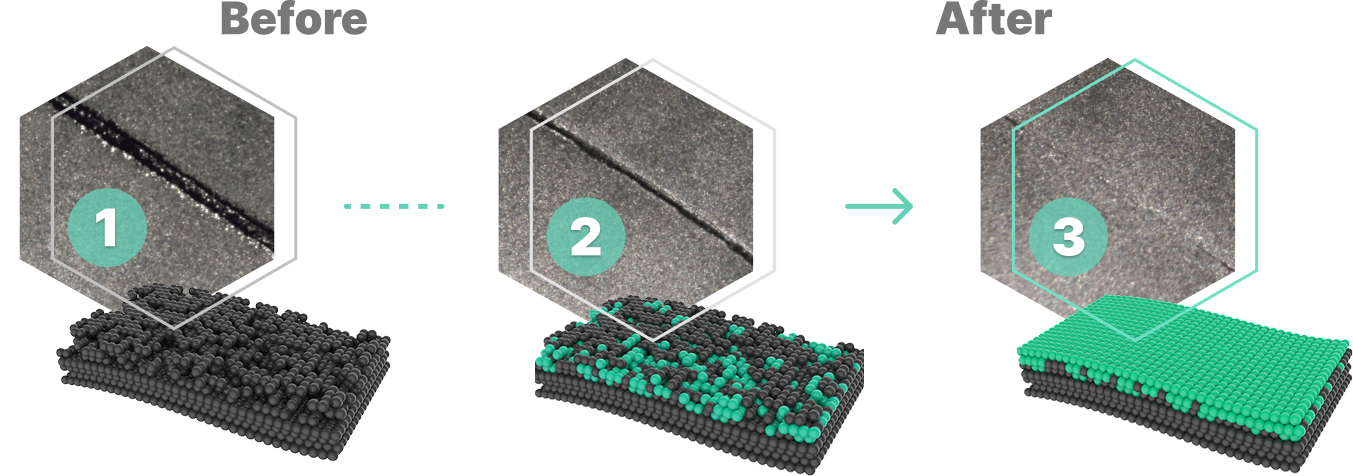

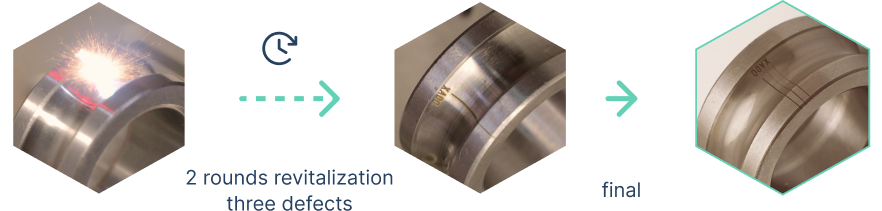

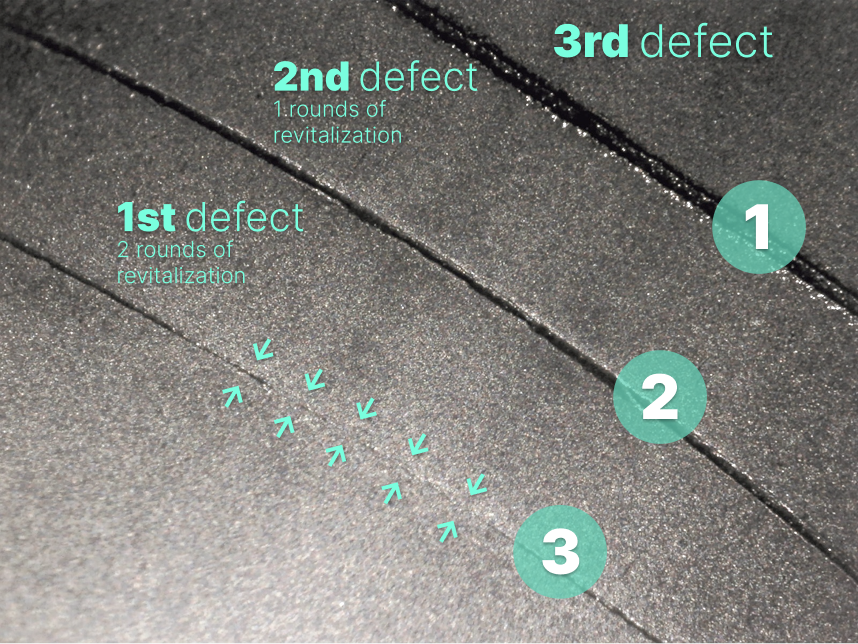

The experiment provides a clear demonstration how REVITALIZANT eliminates and heals intentionally inflicted damages on the operating surface of a rolling bearing.

A laser was used to create transverse scratches (defects 0.05 mm deep and wide) on a new surface and then twice more after every 30 minutes of bearing operation using lubricant with REVITALIZANT.

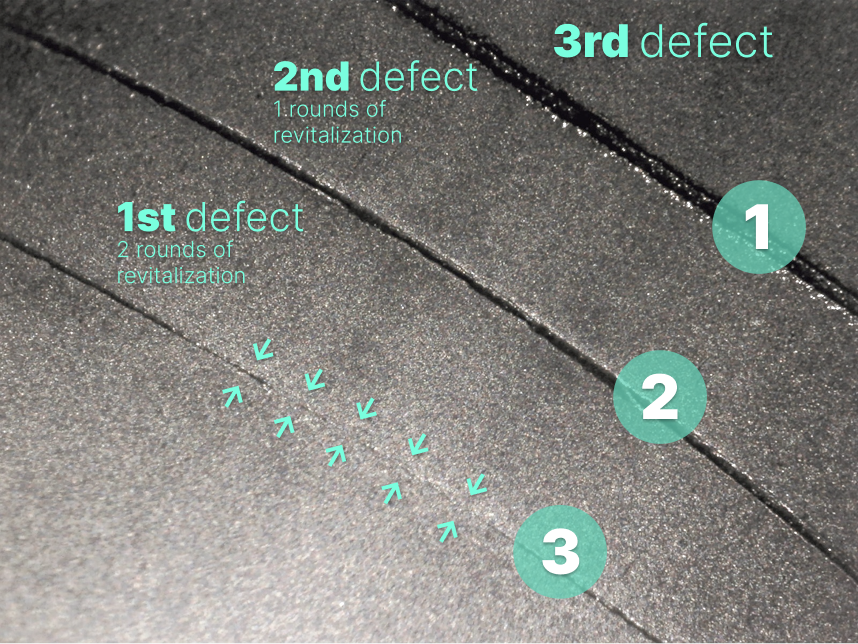

| Magnified image of the operating surface of the bearing after operation with the lubricant containing REVITALIZANT: |

| 1 – control scratch-defect applied after the experiment was completed; |

| 2 – scratch-defect after 30 minutes of bearing operation with the lubricant containing REVITALIZANT. The scratch is healing; the distance between the edges of the defect has decreased more than twofold; |

| 3 – сompletely eliminated defect after 60 minutes of operation with REVITALIZANT! |

The experiment clearly demonstrates the stages of complete removal of surface defects.

REVITALIZANT improves surfaces of new parts!

standard radial ball / roller bearings

standard radial ball / roller bearings super-precision bearings with minimal losses

super-precision bearings with minimal losses

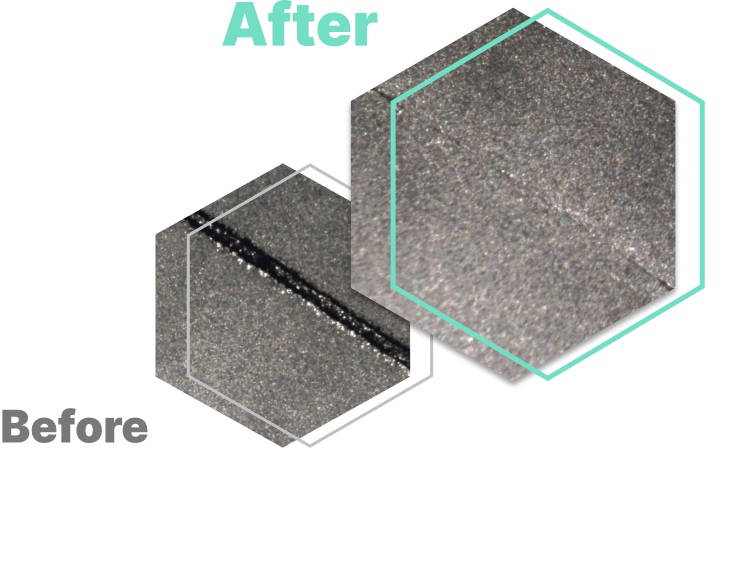

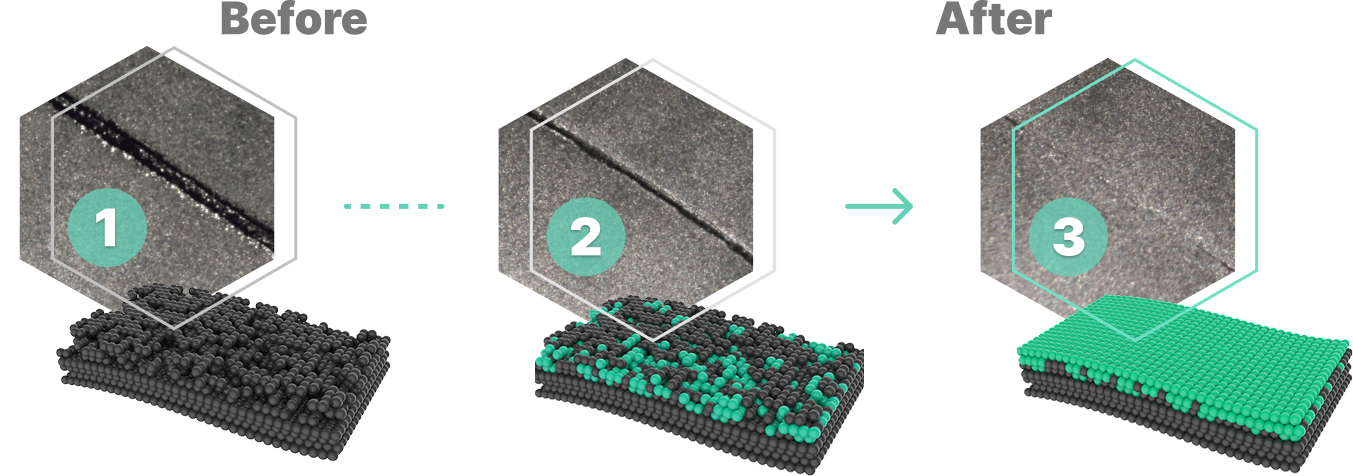

The images represent photographs of a section of the new operating surface of a rolling bearing before and after the application of REVITALIZANT.

In the initial image on the left, with a laser-etched scratch-defect, traces of the factory finish can be seen in the form of roughness from grinding. The ninth grade of surface finish is standard for critical units and bearings.

In the image on the right, after the bearing operation with the lubricant containing REVITALIZANT, it is clear that the defect has been eliminated and the appearance of the surface has changed significantly. Traces of factory grinding have disappeared, and the surface has become uniform and smooth.

The grade of the surface finish has improved, increasing from ninth to the maximum thirteenth. Surfaces of this grade are obtained through time-consuming and expensive polishing. This grade of finish guarantees perfect mating of parts with minimal friction, which is characteristic for high-precision equipment and instruments.

REVITALIZANT not only eliminates defects, but also improves surfaces of new parts and increases their grade of finish.